Back

-

-

Wärmetechnische Produkte

-

Wärmebildkamera

-

-

FALCON 2.0 NEWFALCON 2.0

-

CONDOR LRF 2.0 NEWCONDOR LRF 2.0

-

LYNX 2.0LYNX 2.0

-

LYNX SLYNX S

-

LYNX ProLYNX Pro

-

FALCONFALCON

-

CONDORCONDOR

-

-

Wärmebild-Zielfernrohr

-

-

STELLAR 3.0 NEWSTELLAR 3.0

-

STELLAR 2.0STELLAR 2.0

-

STELLARSTELLAR

-

THUNDER ZOOM 2.0THUNDER ZOOM 2.0

-

THUNDER 2.0THUNDER 2.0

-

-

Wärmebild-Vorsatzgerät

-

-

THUNDER 3.0 NEWTHUNDER 3.0

-

THUNDER 2.0THUNDER 2.0

-

-

Wärmebildkamera für Smartphones

-

-

EXPLOREREXPLORER

-

-

-

Digitale Tag- und Nachtsichtprodukte

-

Multispektrum-Produkte

-

Multispektrum-Monokular

-

-

GRYPHON LRFGRYPHON LRF

-

-

Multispektrum-Binokular

-

-

HABROK Pro NEWHABROK Pro

-

HABROK 4K NEWHABROK 4K

-

HABROKHABROK

-

RAPTORRAPTOR

-

-

-

Wildkamera

-

Wildkamera

-

-

M15M15

-

-

-

Anwendung

-

Anwendung

-

-

HIKMICRO Sight NEWHIKMICRO Sight

-

-

-

Zubehör

-

Infrarot-Taschenlampe

-

-

Infrarot-TaschenlampeInfrarot-Taschenlampe

-

-

Infrarot-Taschenlampe-Halterung

-

-

Infrarot-Taschenlampe-HalterungInfrarot-Taschenlampe-Halterung

-

-

Schiene

-

-

SchieneSchiene

-

-

Ring

-

-

RingRing

-

-

Adapter

-

-

THUNDER 2.0 AdapterTHUNDER 2.0 Adapter

-

Adapter 1.0Adapter 1.0

-

-

Okular

-

-

THUNDER 3.0 Okular NEWTHUNDER 3.0 Okular

-

HUNDER 2.0 OkularHUNDER 2.0 Okular

-

OkularOkular

-

-

Ladegerät

-

-

HABROK Pro Ladegerät NEWHABROK Pro Ladegerät

-

THUNDER 2.0 LadegerätTHUNDER 2.0 Ladegerät

-

18650 Ladegerät18650 Ladegerät

-

21700 Ladegerät NEW21700 Ladegerät

-

-

Akku

-

-

HABROK Pro Batterie NEWHABROK Pro Batterie

-

THUNDER 2.0 BatterieTHUNDER 2.0 Batterie

-

18650 Akku18650 Akku

-

18650 Batterie NEW18650 Batterie

-

-

Monokular Tasche

-

-

Monokular Tasche NEWMonokular Tasche

-

-

Binocular-Tragegurt

-

-

Binocular-Tragegurt NEWBinocular-Tragegurt

-

-

Zubehör für Wildkamera

-

-

Solarpanel NEWSolarpanel

-

-

-

-

-

Tragbare Wärmebildkamera

-

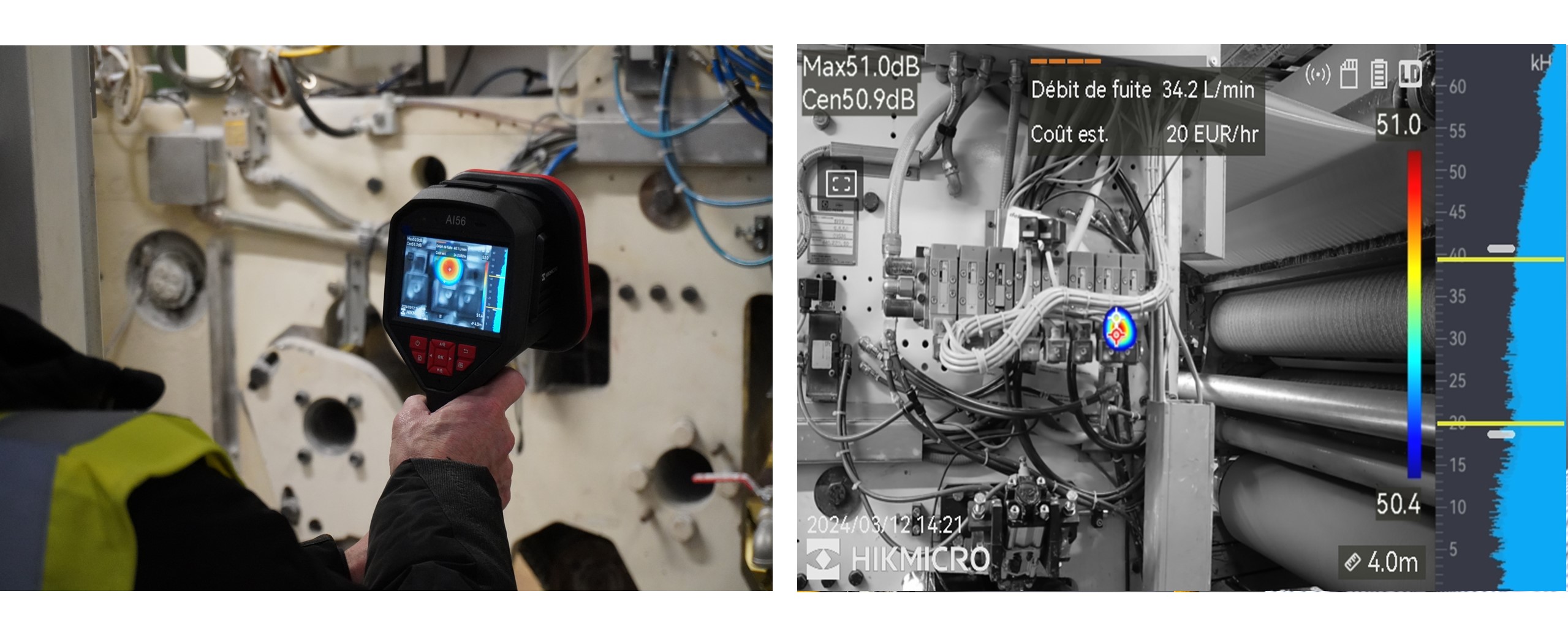

Akustische Handgeräte

-

AI-Serie

-

-

AI56 & AI76AI56 & AI76

-

-

AD-Serie

-

-

AD21 & AD21P NEWAD21 & AD21P

-

-

-

Fest installierte Wärmebildkamera

-

Cube–Serie

-

-

Cube–SerieCube–Serie

-

-

Box-Serie

-

-

Fokusfreie BoxkamerasFokusfreie Boxkameras

-

Autofokus-Kamera NEWAutofokus-Kamera

-

Hohe Temperatur. BoxkameraHohe Temperatur. Boxkamera

-

R&D Boxkameras NEWR&D Boxkameras

-

R&D-Boxkamera mit hoher Bildrate NEWR&D-Boxkamera mit hoher Bildrate

-

-

Hitzeresistente Bullet-Kameras

-

-

Hitzeresistente Bullet-KamerasHitzeresistente Bullet-Kameras

-

-

-

Durchflussmesser

-

-249Elektromagnetischer Durchflussmesser

-

-

FE0 SerieFE0 Serie

-

-

-

Drucktransmitter

-

Drucktransmitter

-

-

PS0-SeriePS0-Serie

-

-

-

Pyrometer

-

Pyrometer

-

-

PD1 SeriePD1 Serie

-

-

-

Software

-

-

-

HIKMICRO ViewerHIKMICRO Viewer

-

-

-

-

HIKMICRO AnalyzerHIKMICRO Analyzer

-

-

-

-

HIKMICRO Analyzer Akustik NEWHIKMICRO Analyzer Akustik

-

-

-

-

HIKMICRO StudioHIKMICRO Studio

-

-

-

-

SpotgrößenrechnerSpotgrößenrechner

-

-

-

Zubehör

-

Linsen

-

-

B-SerieB-Serie

-

Pocket-SeriePocket-Serie

-

M-Serie NEWM-Serie

-

G-SerieG-Serie

-

SP-SerieSP-Serie

-

-

Batterien

-

-

M-SerieM-Serie

-

G/AI-SerieG/AI-Serie

-

FT-Serie NEWFT-Serie

-

SP-SerieSP-Serie

-

-

Ladegerät

-

-

M-SerieM-Serie

-

G/AI-SerieG/AI-Serie

-

SP-SerieSP-Serie

-

FT-Serie NEWFT-Serie

-

-

Halterungen

-

-

Mini/Pocket-SerieMini/Pocket-Serie

-

M-Serie NEWM-Serie

-

SP-SerieSP-Serie

-

-

Taschen

-

-

B-SerieB-Serie

-

M/G/SP/AD-SerieM/G/SP/AD-Serie

-

-

-

-

Lösungen

-

Entdecken

-

Log in -

Wo kann man es kaufen -